History

From tradition to innovation: since the company was founded in 1895, Fehrmann has changed from a classic foundry to an agile innovator in two sectors. Today, we design and manufacture worldwide innovations in the fields of ship's windows and pressure-tight special glazing, and high-performance aluminium alloys.

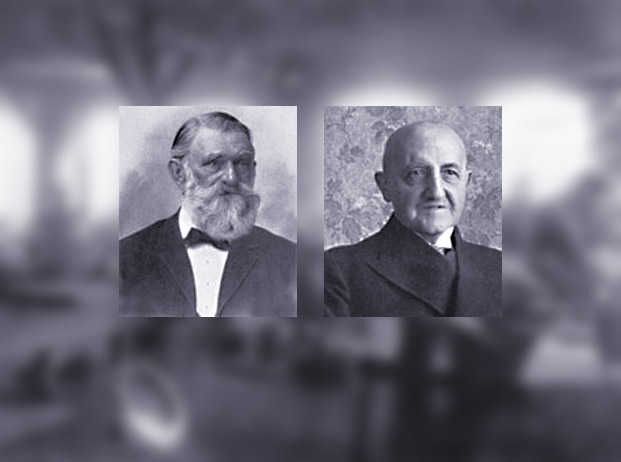

In the year when the Kiel Canal was opened, the retired senior inspector of the Hamburg-America Line, Captain Nicolai Petersen Fehrmann (photo, left) and his son Eduard (right) set up the company OHG N. Fehrmann + Co. The company founders leased a site in Hamburg's free port, and began to supply the shipyards and repair shops with cast metal products.

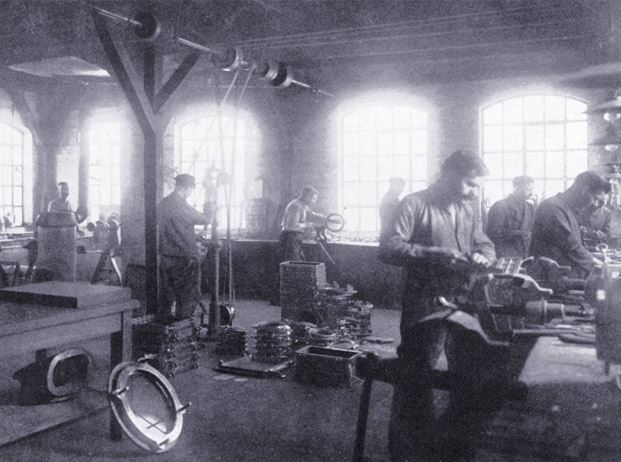

When the Blohm + Voss shipyard set up its own foundry to cast heavy metals, Eduard Fehrmann decided to start manufacturing ship's windows, and set up a mechanical workshop as well as a metalworking shop. Since then, ship's windows made by Fehrmann have had the reputation of a brand product of the highest quality. The photo shows the old metalworking shop with the transmission drive for all the machines.

Completion of a three-floor office building. After the inflation era was over, Kurt Fehrmann started to build up export sales, which represent a large part of our business to this day.

1946

Manufacture of products such as cups and spoons, which were used after the end of the war to barter for potatoes from the Lüneburger Heide so that the company's staff had enough to eat. Construction of a machine hall which gave employment to up to 200 skilled workers.

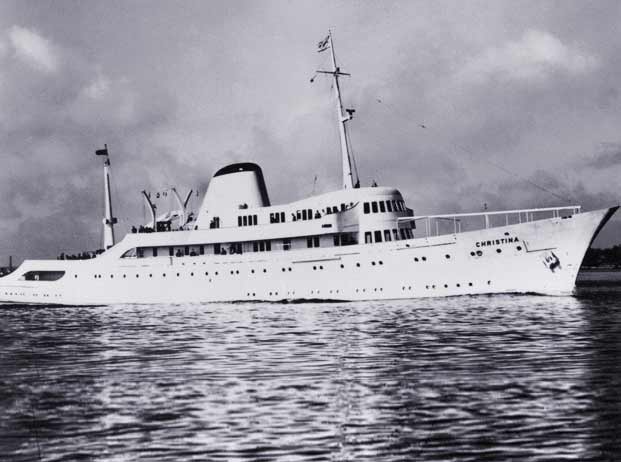

For the first time ever a large-scale modern yacht, the MS Christina, was completely fitted with Fehrmann windows, among them vertical sliding windows resistant to water pressure. A pioneering achievement on the world market.

1963

The purchase of the equipment of the Geyer company in Kiel enabled us to start manufacturing windows made of profiles. This made Fehrmann the biggest German producer of special ship's windows and gave it a substantial share of the European market in this sector. Worldwide export of ship's windows.

1971

The company moved to new premises at Stenzelring in Wilhelmsburg. The next few years saw the development of the VdTÜV materials sheet 469 for ductile corrosion-resistant aluminium alloys.

1981

Development and production of unique special ship windows for the world-famous research vessel MS Polarstern.

1983

Fehrmann became the first company worldwide to develop fire-resistant windows for use in shipbuilding. (Fire protection categories A0 to A60).

1999

Introduction of an ERP system to improve the efficiency of internal processes. Use of modern CNC processing centres for machining cast parts.

2005

Introduction of a quality management system after first certification ISO:9000. Implementation of the 3D construction software Solid Works. New development of electric sliding windows for superyachts.

2006

Development of a window system for installation and replacement without hot works. The window system contains of clamp bars set to the mainframe instead of welded or bolted frames.

Development of VdTUEV materials sheet 551 for ductile copper alloys in cooperation with TÜV Nord. Construction of electrically- / pneumatically-operated glass sliding doors for superyachts. First turnkey project: a fully-glazed yoga room including electric sliding doors and a sliding roof, that was developed, constructed and mounted on the roof of a yacht in record-breaking time.

2008

Development of the world innovation Flushline glass sliding doors for ships. Several patents protect the new product, a weathertight glass sliding door which closes flush with the yacht's bulkhead. Successful type approval for a new electric sliding window for rough seas.

Appointment of Henning Fehrmann, Dipl-Ing., as Managing Director (fifth generation).

2011

Uwe and Henning Fehrmann are awarded the Hamburg Family Entrepreneur of the Year award in Germany's capital of family businesses.

2012

Implementation of the competence centre for the development of high-performance aluminum alloys.

2015

Development of the worldwide unique FFF window system as basis for new ship windows - high strength against strong waves, for increased safety of ship, passengers and crew, very easy to install and for easy exchange/upgrade.

2017

Development of two corrosion resistant ultra high performance aluminum alloys for castings in cooperation with the Helmholtz Centre for Materials Research, Geesthacht.

2018

Development of the first corrosion-resistant high-performance aluminum alloy for 3D printing.

R&D project for the development of intelligent ship windows for research on waves and with augmented reality features in cooperation with several Fraunhofer institutes starts.

2019

Go Live of high performance aluminum powders for 3D Printing.

High performance aluminum F-AL80 qualified for HPDC.

2020

Development of 2nd high performance aluminum powder with increased strength.

High performance aluminum for casting qualified at serial automotive part and at German OEM.

2021

World market portfolio leader for aluminium alloys for 3D printing by developing six new powders in 2021. Qualification of high performance aluminum for extrusion.